When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network. When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

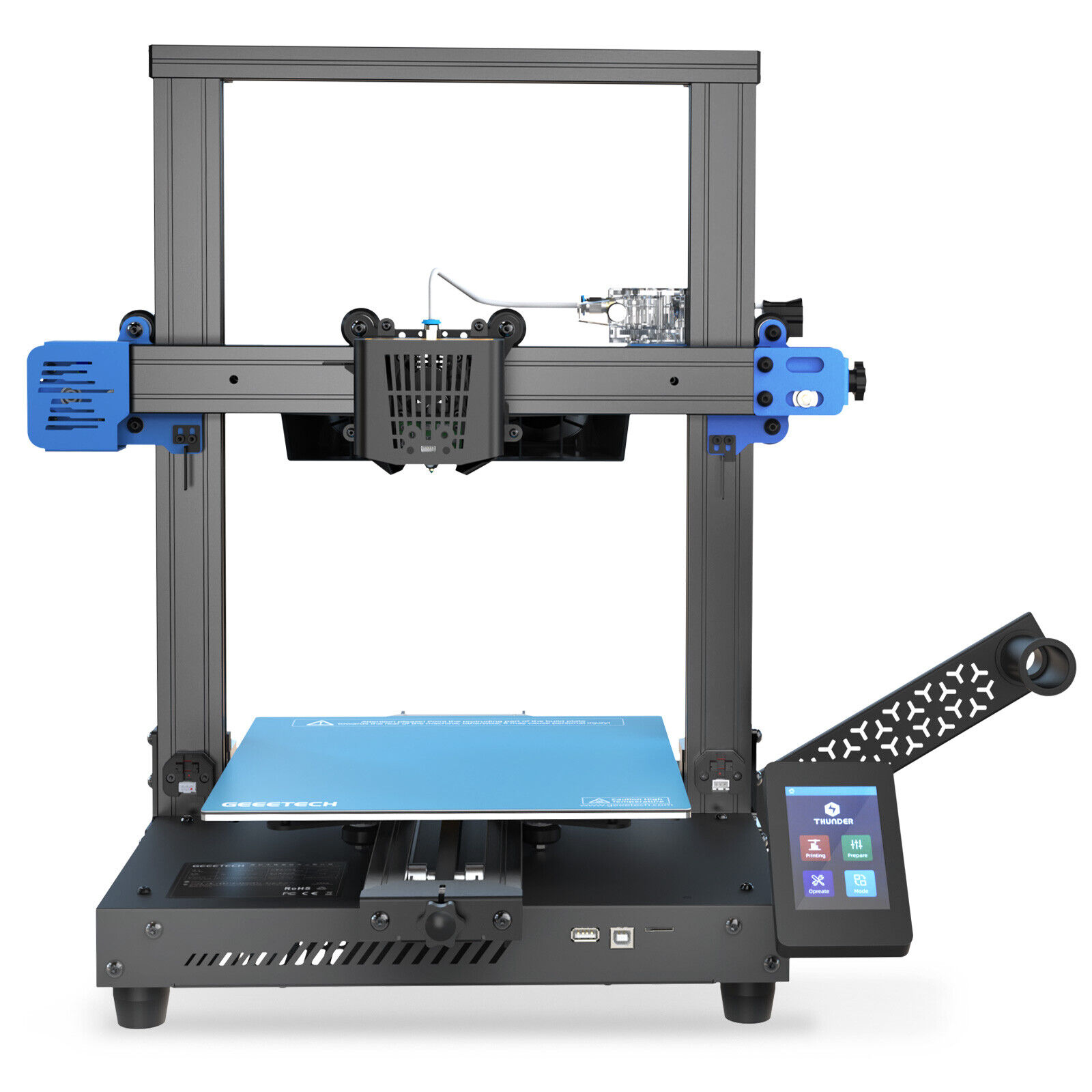

- THUNDERHigh Speed 3D Printer 1.Main Function

- All-mental construction, which is firm and stable;

- High speed 3D printing, the highest speed can reach up to 300mm/s;

- X-axis and Y-axis are equipped withclosed-loop drive,achievingintelligent detection, responsein real-time, and avoiding frommodel dislocation;

- The Y-axis adopts a professional secondary deceleration structure, which can effectively reduce the vibration generated by the printer during high-speed printing and make the hotbed move more smoothly.

- Brand new UI design, which has concise and clear interaction, greatly improvinguser experience;

- In order to cope with high-speed printing, Thunderis equipped with high-efficiency model coolingsystem, which uses 2 high-volume fans, and innovatively designed 2 larger-size and higher-air-volume auxiliary cooling fans;

- Thunder uses an enhanced dual-drive gear extruder, which is more durable and reliable than ordinary extruders;

- High-power hotend heating rod:The hotend heating power is up to 70w, which can effectively ensure high-speed printing;

- In order to solvethefilamentshortagethat may occur in high-speed printing, Thunder adoptsa largevolumenozzle;

THUNDERHigh Speed 3D Printer 1.Main Function - All-mental construction, which is firm and stable;

- High speed 3D printing, the highest speed can reach up to 300mm/s;

- X-axis and Y-axis are equipped withclosed-loop drive,achievingintelligent detection, responsein real-time, and avoiding frommodel dislocation;

- The Y-axis adopts a professional secondary deceleration structure, which can effectively reduce the vibration generated by the printer during high-speed printing and make the hotbed move more smoothly.

- Brand new UI design, which has concise and clear interaction, greatly improvinguser experience;

- In order to cope with high-speed printing, Thunderis equipped with high-efficiency model coolingsystem, which uses 2 high-volume fans, and innovatively designed 2 larger-size and higher-air-volume auxiliary cooling fans;

- Thunder uses an enhanced dual-drive gear extruder, which is more durable and reliable than ordinary extruders;

- High-power hotend heating rod:The hotend heating power is up to 70w, which can effectively ensure high-speed printing;

- In order to solvethefilamentshortagethat may occur in high-speed printing, Thunder adoptsa largevolumenozzle;

- The hotbed build plate is designed with PC film + spring steel sheet + rubber magnetplate, and the model can be removed more easily. Compared with the PEI-coated build plate platform, it offers strongermodeladhesion and is not easy to fall off;

- Thunderis designed with dualZ-axis, which runs more smoothlyandcan effectively improve the printing quality;

- USB-Aand TF dual portsdesign:You can use TFcardor USB flash disk for offline printing, or TFcard andUSB flash disk can be inserted at the same time;

- Thunder has X/Y axis belt quick adjustment kit, allowing users to adjust the X-axis and Y-axis belt tension easily;

- Nozzle LED Lighting:Thunderhas designed an LED near the nozzle, allowing users to easily observe the printing status;

- Password Protection: Prevent parameters from being modified by others during printing;

- Break-Resuming Capability: Thunder has the Break-Resuming Capability, which can prevent printing failure caused by sudden power off;

- Filament Cut Detection: It can detect abnormal condition of filament and automatically suspend printing, which can effectively avoid the waste of filament and time caused by abnormal situations such as filament broken and used up ;

- HotbedRapid Heating: The hotbed can be heated to 110°C in 7 minutes;

- Strict Testing:Key components will be strictly tested before leaving the factory, and technical support will be provided;

- Able to provide ODM and OEM custom design and manufacture;

2.Machine Parameters Technology FDM Printing Thickness 0.1-0.2mm Printing Materials PLA,ABS, PETG, SILK MPLA, Wood Polymer Printing Volume 25*250*260 Auto-leveling Complimentary 3D Touch Leveling Sensor Break-Resuming Capability Yes Hotbed Heating Time(110℃) 7min Nozzle Diameter (mm) 0.4 The NozzleNumber 1 Positional Accuracy X 轴: 0.011mm; Y 轴: 0.011mm; Z 轴: 0.0025mm; Printing Accuracy ±0.1mm Printing Speed Display 3.5-inch Color Touch Screen Slicer Repetier-Host, EasyPrint Lite, Cura Printing File format .Gcode Hotbed Max Temperature 110℃ Nozzle Max Temperature 250℃ Working temperature 10-40℃ 3.ElectricParameters Power Input 115/230V AC, 50/60Hz Powe Supply DC24V-15A Max, 360W Port 1*TF接口, 1*USB-A接口,1*USB-B接口 4.Dimensions Hotbed Size 260*260mm Net Weight 10.7g Packing Weight 13.4kg Machine Size 472(L)*488(W)*525(H)mm Package Size 553(L)*544(W)*330(H)mm

|

|